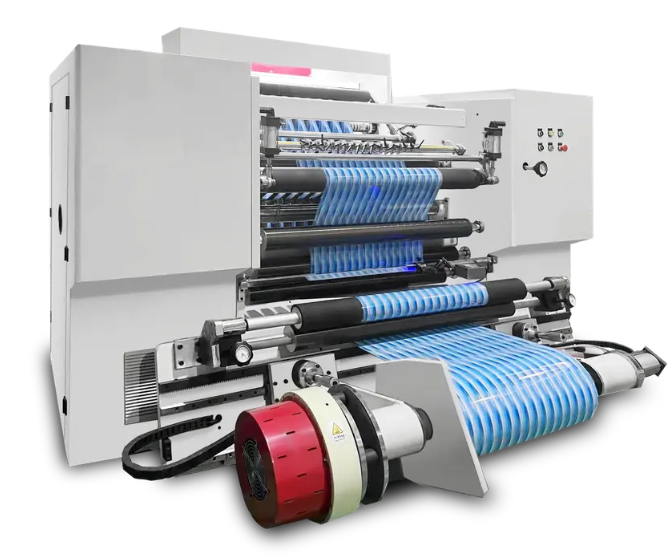

What is a Slitting Machine?

A slitting machine is a versatile piece of equipment used in manufacturing industries to cut large rolls of material into smaller, more manageable widths. These materials can range from paper, plastic, metal, fabric, and even steel, depending on the type of slitting machine in use. Slitting is a critical process for producing products that need precise and clean cuts, such as paper sheets, fabric rolls, metal coils, and packaging materials. In this article, we’ll explore the definition, working mechanism, benefits, types, and applications of a slitting machine.

Definition and Basic Functionality of a Slitting Machine

A slitting machine is designed to cut wide rolls of material into narrower strips, or slits, to meet specific production requirements. It does this by using rotary knives, razor blades, or shearing actions to slice through materials in a controlled, efficient manner. The main purpose of a slitting machine is to reduce a large roll into more usable, precisely sized rolls or sheets.

The process is essential in various industries where the material needs to be cut into smaller rolls or sheets for further processing. The quality of the cuts can vary depending on the type of slitting machine used, with some offering high precision, others prioritizing speed or material compatibility.

Applications of Slitting Machines Across Industries

Slitting machines are used in a wide variety of industries to process different types of materials. Below are some key sectors where these machines play a pivotal role:

Paper Industry: In the paper industry, paper slitting machines are used to cut large rolls of paper into sheets or smaller rolls that can be used for printing, packaging, or other applications. Paper roll slitting machines are especially useful in large-scale production.

Textile and Fabric Industries: In the textile industry, fabric slitting machines or fabric roll slitting machines are used to cut wide rolls of fabric into narrow strips, which are essential for garment manufacturing, upholstery, and more.

Metal Processing: For industries that deal with large steel sheets or coils, steel slitting machines are used to slice the metal into narrower strips, which can be further processed into various metal products.

Packaging: Slitting machines are crucial in the packaging industry, where they are used to cut films, plastic wraps, and other flexible materials used for packaging.

Printing: In printing, slitting machines are used to trim and cut paper or other materials into appropriate sizes and shapes.

How Does a Slitting Machine Work?

Understanding how a slitting machine works requires an exploration of its key components and the process by which it cuts materials into smaller widths.

Key Components of a Slitting Machine

Unwinder: This is where the large roll of material is placed. It feeds the material into the slitting machine.

Slitting Blades: The slitting machine uses rotary knives, shear blades, or razors to slice through the material.

Rewinder: After slitting, the smaller rolls are wound onto new cores, forming new rolls of desired width.

Guiding System: This ensures the material is correctly aligned as it passes through the machine.

Control System: Most slitting machines today come equipped with a computerized control system that ensures accurate cutting and allows operators to adjust the width of slits.

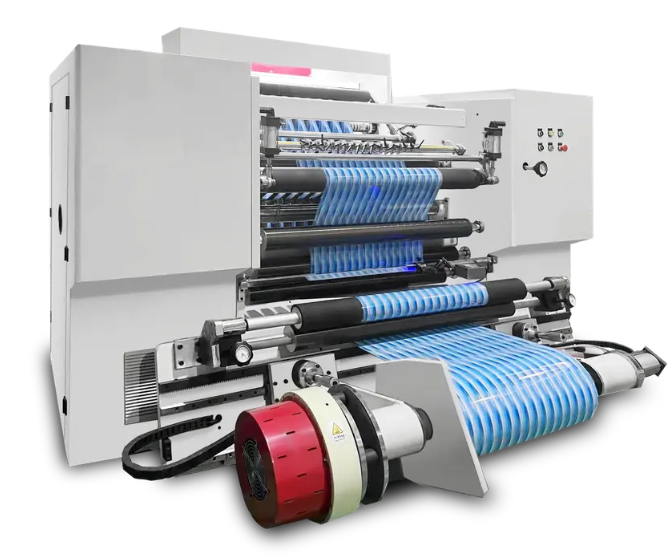

The Slitting Process Explained

The slitting machine works by unrolling the large material from the unwinder and feeding it through a series of slitting blades. These blades can be positioned at specific intervals to cut the material into narrower strips. As the material passes through, the slitting blades slice it precisely, creating a series of smaller rolls or sheets. The material is then rewound onto new cores to form the finished product.

In some cases, multiple blades can be used simultaneously to produce several strips at once, increasing the speed of the process. The slitting process is often fully automated, with the machine adjusting cutting speeds, blade positions, and tension according to the material being processed.

Types of Slitting Methods Used in Machines

Rotary Slitting: This method uses circular blades to slice through the material, offering high speed and precision. Rotary slitting is ideal for cutting flexible materials like paper, film, and fabric. The blades rotate continuously to slice the material as it moves through the machine.

Shear Slitting: This method involves the use of two knives that shear the material as it passes through them. Shear slitting is used for cutting more rigid materials, such as thicker plastics or metals, and it tends to produce a cleaner, more accurate cut compared to other methods.

Razor Slitting: In this method, razor-sharp blades slice the material with minimal pressure, making it ideal for delicate materials such as thin films, paper, or foil. It provides extremely clean edges with little distortion.

Hot Knife Slitting: This technique uses a heated blade to slice through materials. The hot blade helps reduce material stretching or fraying, especially when cutting through materials such as fabric or plastics that might otherwise fray under a standard slitting process.

Different Types of Slitting Machines

Slitting machines come in various configurations depending on the material they are designed to process and the cutting method they use.

Rotary Slitting Machines

Rotary slitting machines are commonly used to cut materials like paper, plastic films, and fabrics. These machines feature rotating blades that continuously slice through the material, making them suitable for high-speed and continuous operations.

Shear Slitting Machines

For materials that require more robust cutting methods, shear slitting machines are used. These machines use two knives (one fixed and one movable) that shear the material, making them ideal for cutting heavier and thicker materials, such as metals or thick plastics.

Razor Slitting Machines

Razor slitting machines are ideal for delicate materials that need precise, clean cuts without causing deformation or damage. These machines use razor-sharp blades to create slits, making them suitable for applications in industries like printing, packaging, and textiles.

Hot Knife Slitting Machines

In some cases, a hot knife slitting machine is the best option for cutting materials that may stretch or fray easily, such as fabrics or synthetic materials. The heated blade prevents the edges from fraying and gives the material a cleaner cut. These machines are commonly used in the fabric and textile industries.

Benefits of Using a Slitting Machine

Slitting machines offer several advantages that make them invaluable in industrial applications, particularly when it comes to precision, speed, and versatility.

Precision and Accuracy in Cutting

One of the primary benefits of using a slitting machine is the level of precision it provides. Slitting machines can cut materials to very specific widths, allowing manufacturers to produce products that meet exact specifications. Whether it's paper slitting machines or fabric slitting machines, the cuts made by these machines are clean and accurate, minimizing waste and improving overall production efficiency.

High Efficiency and Speed

Slitting machines operate at high speeds, allowing large quantities of material to be processed in a short amount of time. This makes them ideal for high-volume production environments where speed is crucial. For example, a paper roll slitting machine can quickly process large paper rolls, cutting them into smaller sheets or rolls without significant downtime.

Versatility for Different Materials

Another significant advantage of slitting machines is their versatility. Whether you're working with paper, metal, fabric, or plastic, there's a slitting machine tailored for the job. Machines like steel slitting machines or material slitting machines are designed to handle different types of materials with ease, providing an effective solution for a wide range of industries.

Slitting Machines in Various Industries

Slitting machines play a crucial role in multiple industries, providing efficient, high-precision cuts for a wide range of materials. Below are some of the key industries that benefit from slitting machine technology:

Slitting Machines in the Packaging Industry

In the packaging industry, slitting machines are used to cut plastic films, paper, and other packaging materials into precise widths for use in packaging products. The ability to produce consistent, high-quality cuts makes slitting machines invaluable for packaging manufacturers.

Slitting Machines for Paper and Film Industries

Paper slitting machines and paper roll slitting machines are widely used in the paper industry to cut large paper rolls into smaller, more manageable sheets. Similarly, in the film industry, slitting machines are used to cut plastic or film materials into rolls of the desired width.

Slitting Machines in the Metal Processing Industry

The steel slitting machine is a critical tool in the metal processing industry. It is used to cut large coils of metal into narrower strips, which are then used for a variety of applications, including automotive manufacturing, construction, and appliance production.

How to Choose the Right Slitting Machine?

Choosing the right slitting machine is essential to ensuring efficient operations and high-quality cuts. There are several factors to consider when selecting a slitting machine, including the type of material being processed, the desired cutting precision, and the machine's speed.

Factors to Consider When Selecting a Slitting Machine

Material Type: Whether you're slitting paper, fabric, plastic, or metal, it's important to select a machine that is designed for the material you'll be working with.

Cutting Precision: The required precision level will determine the type of slitting machine you need. For example, razor slitting machines offer the highest precision for delicate materials.

Production Speed: If you're processing large volumes of material, choose a machine with high-speed capabilities.

Common Issues and Troubleshooting Tips

Common issues include blade wear, misalignment, or inconsistent cutting. Regular maintenance and proper adjustments can help minimize these issues.

Maintenance and Care for Slitting Machines

Regular maintenance is crucial for extending the lifespan of your slitting machine. This includes checking blade sharpness, ensuring proper tension in the material, and periodically cleaning and lubricating components.

Conclusion: Is a Slitting Machine Worth the Investment?

Recap of Key Benefits

In summary, slitting machines are essential for cutting large rolls of material into smaller, more manageable sizes. They offer precision, efficiency, and versatility, making them valuable tools across industries such as paper, textiles, metal processing, and packaging.

Future Trends in Slitting Technology

As manufacturing continues to advance, the future of slitting machines lies in automation and enhanced cutting technologies. With developments in AI and robotics, slitting machines will become even more precise, faster, and adaptable to a wider variety of materials.

Final Thoughts on Choosing a Slitting Machine

Investing in a slitting machine can significantly enhance production efficiency, especially for industries that require large-scale cutting operations. Whether you're processing paper, fabric, or steel, selecting the right machine based on your needs will help you achieve the best results while maintaining cost-efficiency and quality standards.