What is a Plastic Recycling Machine That Pays You?

Plastic pollution is one of the most pressing environmental issues facing our planet today. With millions of tons of plastic waste ending up in landfills, oceans, and natural habitats every year, the need for effective solutions is more urgent than ever. One such solution is the plastic recycling machine, which allows individuals and businesses to recycle plastic materials and even earn money in the process. But what exactly is a plastic recycling machine that pays you? This article will explore this innovative concept, shedding light on how these machines work, the benefits they offer, and how you can get started with one.

The Growing Problem of Plastic Waste

Plastic is a versatile material used in countless everyday products, from packaging and bottles to electronics and automotive parts. However, its durability and resistance to decomposition mean that it takes hundreds, sometimes even thousands, of years to break down in the environment. As a result, plastic waste accumulates at an alarming rate, polluting oceans, harming wildlife, and contributing to global environmental crises.

The statistics are staggering: According to a 2020 report by the Ellen MacArthur Foundation, over 300 million tons of plastic are produced annually, and more than 8 million tons of plastic end up in the ocean each year. In the face of such a large-scale environmental issue, finding ways to recycle plastic efficiently is more important than ever.

How Can a Plastic Recycling Machine Solve This Problem?

A plastic recycling machine offers a practical solution to the global plastic waste problem. These machines break down plastic waste, turning it into reusable material that can be used in manufacturing new products. By facilitating the recycling process, these machines not only help reduce the volume of waste but also conserve resources, reduce pollution, and promote sustainability.

Moreover, certain plastic recycling machines have been designed to pay users for their recycling efforts, creating a financial incentive to recycle. This has led to the creation of innovative machines that allow both individuals and businesses to turn plastic waste into profit.

The Concept of "Getting Paid" for Recycling

The idea of a plastic recycling machine that pays you involves a system where users can bring their plastic waste to the machine, which then processes it into valuable materials, such as plastic pellets or reprocessed plastic sheets. In return, the user receives a monetary reward, such as cash, credits, or vouchers that can be redeemed for products or services.

This "pay-for-plastic" model is gaining popularity, particularly in regions with high levels of plastic waste. Cities and businesses are increasingly adopting this model to encourage individuals to recycle more, reduce waste, and take responsibility for the environment.

How Do Plastic Recycling Machines Work?

To understand how plastic recycling machines work, it’s important to know the basic principles behind them and the types of machines available. The general process involves collecting plastic waste, breaking it down into smaller pieces, and then converting it into a form that can be reused in manufacturing.

Basic Principles of Plastic Recycling Machines

A plastic recycling machine typically works through several key stages:

Collection and Sorting: The first step involves gathering plastic waste, which may include items like bottles, bags, and containers. Often, this material needs to be sorted into different types of plastic for more efficient recycling.

Shredding: The collected plastic is fed into the machine’s shredder, which cuts it into smaller pieces, making it easier to process further.

Melting and Extrusion: The shredded plastic is then melted down and passed through an extruder to form new shapes or pellets, which can be used to create new plastic products.

Cooling and Shaping: The molten plastic is cooled and formed into usable shapes, such as pellets, sheets, or filaments, which can be used in various applications.

Packaging: Finally, the recycled material is packaged and ready for resale or use in new products.

Types of Plastic Recycling Machines

There are several types of plastic recycling machines, each designed for different purposes and scales of operation. The most common types include:

Plastic Bottle Recycling Machines: These machines are specifically designed to recycle plastic bottles, such as PET bottles, which are some of the most commonly used and discarded plastic items. They typically involve shredding, melting, and reforming the plastic into new products.

Waste Plastic Recycling Machines: These machines can process various types of plastic waste, including packaging materials, containers, and even plastic products from industries like automotive or electronics.

Automatic Plastic Recycling Machines: As the name suggests, these machines are automated, requiring little human intervention. They streamline the entire recycling process, from collection and sorting to shredding and extrusion.

DIY Plastic Recycling Machines: These are small-scale machines designed for home use, allowing individuals to recycle plastic waste in their own homes. They are ideal for hobbyists or those looking to reduce their personal plastic waste footprint.

Commercial Plastic Recycling Machines: Larger-scale machines designed for commercial use, typically by businesses or recycling facilities. These machines can process large volumes of plastic waste and produce recycled material for resale or use in manufacturing.

The Process of Turning Plastic Waste into Reusable Materials

The process of turning waste plastic into reusable materials involves several stages:

Sorting: The plastic waste is sorted based on material type, such as PET, PVC, or HDPE. Sorting ensures that the recycling process is more efficient and prevents contamination.

Shredding: The sorted plastic is then shredded into smaller pieces. This makes it easier to melt and reprocess.

Melting: The shredded plastic is heated to a high temperature, turning it into a liquid form. The melted plastic is then extruded into new shapes or pellets.

Cooling and Pelletizing: The molten plastic is cooled and shaped into pellets or sheets, which are ready for reuse in manufacturing new products.

Recycling and Repurposing: The final recycled material can be repurposed for a variety of applications, such as manufacturing new plastic bottles, packaging, or even furniture and clothing.

Benefits of Plastic Recycling Machines That Pay You

Using a plastic recycling machine that pays you offers a variety of benefits, not just for the individual but for society as a whole.

Environmental Benefits

The primary environmental benefit of plastic recycling machines is the reduction in plastic waste. By turning plastic waste into reusable materials, these machines help reduce the amount of plastic that ends up in landfills or oceans. This, in turn, helps reduce pollution, protect wildlife, and conserve natural resources.

Financial Incentives and Profitability

One of the most compelling reasons for individuals to use plastic recycling machines that pay you is the financial incentive. By recycling plastic waste, users can earn money or credits that can be used for a variety of purposes. For businesses, investing in commercial plastic recycling machines can reduce waste disposal costs and even generate additional revenue by selling recycled plastic materials.

Community and Societal Impact

Plastic recycling machines also have a positive impact on communities. They encourage individuals to participate in recycling efforts, raising awareness about the importance of reducing plastic waste. Communities that adopt these machines can foster a culture of sustainability, helping to build a cleaner, greener future for everyone.

Popular Plastic Recycling Machines That Pay You

There are various types of plastic recycling machines available for individuals and businesses alike. Here are some popular options:

Machines Available for Individuals

For individuals looking to recycle plastic at home, plastic recycling machines at home provide a convenient solution. These machines allow users to recycle small amounts of plastic waste, such as bottles and containers, and turn them into reusable material. Some DIY machines even allow users to create new products, such as plastic jewelry or home decor items.

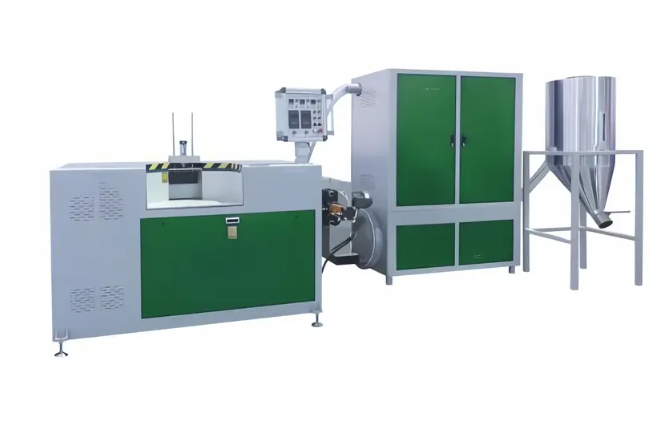

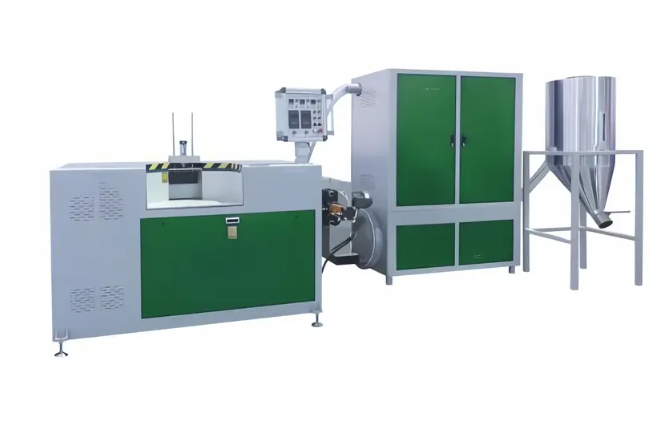

Industrial Plastic Recycling Machines for Large-Scale Operations

For businesses or large-scale operations, commercial plastic recycling machines are the ideal choice. These machines can process large quantities of plastic waste, providing a steady supply of recycled material for use in manufacturing new products. They can be a significant investment but offer substantial long-term benefits in terms of cost savings and revenue generation.

Review of Top Plastic Recycling Machines

Some of the top-rated plastic recycling machines on the market today include:

Precious Plastic Machines: A series of DIY machines that can be used to recycle plastic at home or in small workshops. These machines include a shredder, extruder, and injection molding machine, allowing users to create a wide range of products.

Enstyro Machine: A compact and affordable machine designed for small-scale plastic recycling at home. It can process plastic waste into filaments for 3D printing.

Zerma Plastic Recycling Machines: A leading manufacturer of industrial-scale recycling machines, Zerma offers a range of automatic plastic recycling machines that are designed to handle high volumes of plastic waste efficiently.

How to Get Started with a Plastic Recycling Machine That Pays You?

If you're interested in using a plastic recycling machine that pays you, here are the key steps to getting started:

Choosing the Right Plastic Recycling Machine

The first step is to choose the right machine for your needs. For individuals, a DIY plastic recycling machine or a small plastic bottle recycling machine may be sufficient. For businesses, investing in a commercial plastic recycling machine will be necessary to handle larger volumes of plastic waste.

Setting Up and Operating the Machine

Once you've selected your machine, the next step is to set it up and begin operating it. This may involve installing the machine, learning how to use it, and ensuring that you're following all safety and environmental guidelines.

Tips for Maximizing Earnings from Plastic Recycling

To maximize your earnings from a plastic recycling machine, consider sorting and cleaning your plastic waste before processing it. The cleaner the material, the higher the quality of the recycled product, which can lead to higher returns. Additionally, some machines offer additional features like the ability to create higher-value products, such as plastic pellets for resale.

Conclusion: Is a Plastic Recycling Machine Worth the Investment?

Recap of Key Points

Plastic recycling machines offer an innovative solution to the growing problem of plastic waste. These machines can help individuals and businesses recycle plastic efficiently, turning waste into valuable resources. Moreover, certain plastic recycling machines even provide a financial incentive by paying users for recycling.

Future of Plastic Recycling Machines That Pay You

As environmental concerns continue to rise, the demand for plastic recycling machines is likely to increase. The future of these machines lies in further automation, greater accessibility for individuals, and more widespread adoption by businesses and communities.

Final Thoughts on Investing in Plastic Recycling Machines

Investing in a plastic recycling machine can be a smart move, both environmentally and financially. Whether you're looking to recycle plastic at home or scale up your business's recycling efforts, these machines offer a practical and profitable solution to the plastic waste crisis.