In the world of commercial printing, the push for higher quality and more vibrant prints has led to significant advancements in printing technology. One such advancement is the development of 8-color printing machines, which offer far superior color reproduction compared to traditional 4-color printing. This advanced technology allows for the printing of more precise, richer, and more detailed images, making it highly popular in industries that require the utmost quality, such as fine art printing, high-end marketing materials, and packaging.

But what exactly is the technology behind these 8-color printing machines? How do they work, and why are they considered a significant leap over traditional 4-color printing? In this article, we will break down the mechanics and benefits of 8-color printing, explaining how it operates, its applications, and why it is a powerful tool for businesses looking to elevate their printing capabilities.

What is 8-Color Printing?

Before delving into the technology, let’s first define what 8-color printing is. Traditional printing methods, such as 4-color printing (also known as CMYK), use a mix of four basic colors to produce a wide spectrum of shades. These colors are:

Cyan (C) – A blue-green color.

Magenta (M) – A red-pink color.

Yellow (Y) – A bright yellow color.

Black (K) – Often referred to as "key," black provides depth and contrast.

These four colors are mixed in varying proportions to create a broad range of colors and shades. In contrast, 8-color printing utilizes eight different inks to create an even more vibrant and accurate color range.

In addition to the four basic CMYK colors, an 8-color printer uses additional spot colors, which may include:

Light Cyan (LC)

Light Magenta (LM)

Orange (O)

Violet (V)

By incorporating these additional colors, 8-color printing machines can produce more subtle gradients, better color accuracy, and more lifelike images, particularly for detailed photographs or complex designs.

How Does an 8-Color Printing Machine Work?

The operation of an 8-color printing machine is similar to traditional 4-color printing, but with added complexity due to the additional colors. Here is an overview of how 8-color printing works:

1. Color Separation

When a digital file is submitted for printing, it first undergoes a color separation process. This process splits the image or design into its individual color components based on the inks available in the machine. In 4-color printing, the design is separated into four color channels: cyan, magenta, yellow, and black.

In an 8-color printing machine, the file is split into eight channels: cyan, magenta, yellow, black, light cyan, light magenta, orange, and violet. The additional channels allow for more precise color rendering by capturing subtle variations in the image that would otherwise be impossible to reproduce with just four colors.

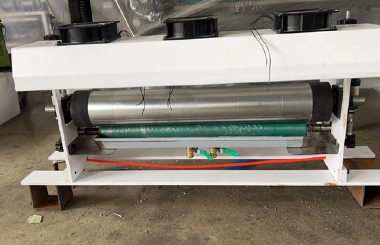

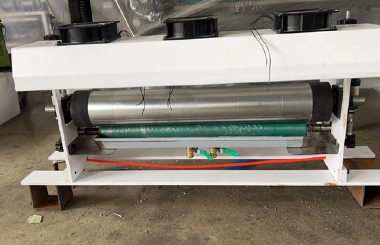

2. Printing Plates

Once the color separation is complete, each of the eight color channels requires a printing plate or printing sleeve (in the case of flexographic printing). These plates are coated with a photopolymer material that has been exposed to ultraviolet light in a pattern that matches the design. The plate holds the ink for each color and transfers it to the paper or substrate.

In an 8-color printing machine, there are eight separate printing plates, each responsible for transferring one of the eight colors to the surface. The plates are mounted on the press, each one aligned perfectly with the others to ensure that the colors are printed in the correct sequence and register.

3. Inking System

The inks used in 8-color printing machines are stored in ink fountains, which supply the appropriate ink to each plate. Each fountain is carefully calibrated to release the correct amount of ink for its designated color. The extra colors, such as light cyan, light magenta, orange, and violet, require additional ink stations, making the inking system more complex compared to 4-color printing.

The advanced ink control systems in 8-color printers ensure that the right amount of ink is applied consistently across the printing press, maintaining the desired color intensity and quality.

4. The Printing Process

Once the plates are inked, the printing press begins the process of applying the ink to the substrate (paper, cardboard, etc.). Each plate passes over the material in succession, one color at a time, starting with the first color and moving to the next in the sequence. In the case of 8-color printing, this means that eight passes are made, one for each ink color.

The result is a composite image that, when viewed by the naked eye, appears as a full spectrum of colors, even though each layer consists of only one color of ink. By carefully blending the eight colors in specific proportions, the printing machine is able to reproduce a much wider range of colors and gradients, producing images that are sharper, more detailed, and more realistic.

Why Use 8-Color Printing?

8-color printing offers several advantages over traditional 4-color printing, particularly in industries where image quality is of the utmost importance. Let’s explore the key reasons why businesses may opt for 8-color printing:

1. Superior Color Accuracy and Depth

One of the most significant benefits of 8-color printing is its ability to achieve superior color accuracy. With four colors (CMYK), there are certain colors and gradients that cannot be replicated with high precision. By adding light cyan and light magenta inks, 8-color printing machines can produce smoother gradients, more accurate color reproduction, and finer tonal details. This is particularly important for high-quality printing, such as photographs, fine art prints, or detailed product images, where precise color matching is crucial.

2. Vibrant and Lifelike Images

The additional colors in an 8-color printing system allow for more vibrant and lifelike images. For instance, the orange and violet inks are used to extend the color gamut, making it easier to reproduce bright oranges, reds, and purples that may be difficult to achieve with only CMYK inks. This results in more vivid prints that appear sharper, more dynamic, and closer to the original design.

3. Better Gradient Transitions

8-color printing excels at handling smooth transitions between colors, a critical feature for designs involving gradients or subtle variations in tone. The addition of light cyan and light magenta inks helps eliminate the appearance of color banding, which can often occur when gradients are printed with fewer colors. As a result, prints have a smoother, more polished look, with more accurate blends between colors.

4. Improved Detail and Texture

The ability to use additional colors also enhances the level of detail in printed images. Fine details, such as facial features in photographs or intricate design elements in illustrations, are much clearer and more defined when printed with 8 colors. The ability to replicate these fine details is especially useful in industries such as photography, packaging, and art printing, where every pixel or brushstroke matters.

5. Consistency Across Large Runs

When it comes to printing large quantities of materials, maintaining color consistency across each print run is crucial. 8-color printing machines can help achieve better consistency over longer print runs, ensuring that each print is nearly identical in terms of color and quality. This is especially beneficial for packaging materials or promotional products where uniformity in color is essential.

Applications of 8-Color Printing

The advanced color capabilities of 8-color printing make it ideal for industries and applications where high-quality prints are a necessity. Let’s look at some key areas where 8-color printing is commonly used:

1. Photography and Fine Art Prints

For photographers and artists who need to reproduce their works with the highest level of fidelity, 8-color printing provides the best possible color accuracy. Photographic prints benefit from the extra inks, which allow for finer detail, smoother gradients, and more vibrant colors. Fine art prints also benefit from the precision and depth that 8-color printing provides.

2. Packaging and Labels

In the world of packaging, especially for high-end or luxury products, the quality of the print job can significantly affect the product’s perceived value. 8-color printing is often used for product packaging, labels, and custom cartons, ensuring that colors are rich, accurate, and consistent. Brands that want to make a strong visual impact with their packaging can benefit from the vibrant color range offered by 8-color presses.

3. Marketing and Advertising Materials

For businesses producing brochures, catalogs, and promotional materials, 8-color printing offers a way to stand out with high-quality visuals. The ability to print vibrant, lifelike images can help attract attention and engage customers more effectively. Whether it’s a full-color brochure or a product catalog, 8-color printing can give your marketing materials an edge over competitors.

4. Textiles and Apparel Printing

In the textile industry, 8-color printing machines are used to create intricate designs on fabrics, including fashion apparel, upholstery, and home goods. The ability to print precise color gradients and complex patterns ensures that designs look sharp, vivid, and true to life.

Conclusion

8-color printing represents a significant advancement over traditional 4-color printing, offering superior color accuracy, vibrancy, and detail. The technology behind these machines allows businesses to produce prints that are visually stunning and precise, making them ideal for applications that require high-quality images, such as fine art prints, luxury packaging, and photographic reproductions.

For industries where color fidelity and image quality are paramount, investing in 8-color printing technology can provide a distinct competitive advantage. Whether you're looking to create eye-catching marketing materials or produce premium product packaging, understanding the capabilities of 8-color printing can help you make an informed decision about the best printing solution for your business.