In the fast-evolving world of commercial printing, the need for high-quality, efficient, and cost-effective printing solutions has never been greater. Whether you are in the packaging industry, producing marketing materials, or creating fine art prints, the quality of your prints plays a crucial role in the success of your business. As businesses look to streamline their operations while maintaining top-tier quality, an 8-color printing machine has become an increasingly popular choice.

In this article, we will explore the key advantages of using an 8-color printing machine, focusing on how it can balance cost efficiency with output quality. We will examine how these machines operate, their cost-effectiveness in the long run, and the significant improvements they bring to output quality. By the end, you’ll have a better understanding of why investing in an 8-color printing machine could be a game-changer for your business.

The Role of 8-Color Printing in Modern Printing Operations

Traditional printing methods have typically relied on a 4-color printing process, known as CMYK (Cyan, Magenta, Yellow, and Black), which creates a full spectrum of colors by mixing these four base inks. While 4-color printing is sufficient for many applications, it can fall short when it comes to producing highly detailed, vibrant, or complex images. This is where 8-color printing comes into play.

An 8-color printing machine uses additional colors, usually including light cyan, light magenta, orange, and violet, alongside the traditional CMYK colors. These additional colors allow the machine to produce a wider color gamut, resulting in more accurate and vibrant prints. The extra colors are particularly beneficial for applications like high-end packaging, fine art prints, and detailed marketing materials where precision and vibrancy are paramount.

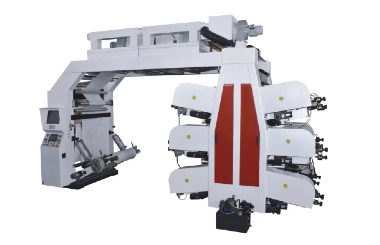

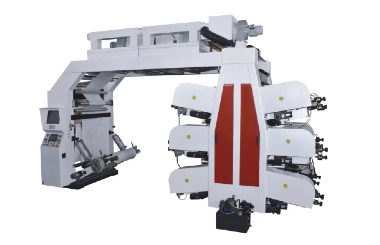

How an 8-Color Printing Machine Works

Understanding how an 8-color printing machine operates helps clarify why it is so beneficial for achieving superior print quality. The process begins with color separation, where the image or design is broken down into its individual color components. In 4-color printing, this involves separating the image into the four CMYK channels. In 8-color printing, the image is separated into eight channels, incorporating light cyan, light magenta, orange, and violet.

Each of these eight color channels is transferred to a separate printing plate. These plates are then mounted on the press, where they feed ink onto the substrate, one color at a time. The additional colors, such as light cyan and light magenta, help produce smoother gradients, better color transitions, and a greater range of hues.

The printing process involves precise alignment of the plates, ensuring that each color is applied in the correct position. The use of advanced technology allows for perfect registration, ensuring that the colors align perfectly and produce crisp, clear images. With eight colors in play, the final output boasts more vibrant and realistic color reproduction compared to traditional 4-color prints.

Cost Efficiency of an 8-Color Printing Machine

When businesses first consider upgrading to an 8-color printing machine, one of the main concerns is cost. These machines are typically more expensive than their 4-color counterparts, and the higher initial investment might seem daunting. However, when you consider the long-term benefits, the cost efficiency of an 8-color printer becomes clear.

1. Reduced Need for Spot Colors

In traditional 4-color printing, businesses often have to use spot colors to match specific brand colors or to achieve certain hues that the CMYK process cannot produce. This requires additional printing steps, increasing both production time and material costs. An 8-color printing machine, with its extended color range, can reproduce many of these spot colors without the need for separate inks. This leads to significant cost savings in both ink and labor.

2. Fewer Reprints and Corrections

One of the primary challenges in printing is achieving the desired color consistency across all print jobs. In a 4-color printing process, slight inconsistencies in color can lead to a need for reprints or corrections, especially in high-volume runs. An 8-color printer, with its greater color accuracy and range, reduces the likelihood of such errors, resulting in fewer reprints and less wasted material. This not only saves money but also increases efficiency and reduces overall production costs.

3. Better Yield with Less Waste

An 8-color printing machine can produce high-quality prints with less waste of both ink and materials. The printer’s ability to reproduce a broader range of colors means that it can achieve more vibrant and detailed prints without requiring as much ink. Additionally, since the colors are more accurately reproduced in the initial print, the need for adjustments and color corrections during the print run is reduced. This leads to better yield and less waste, further improving the cost efficiency of the machine.

4. Long-Term Investment

While the upfront cost of an 8-color printing machine may be higher, its ability to produce high-quality prints consistently and efficiently over the long term can offset this initial investment. The machine’s durability, fewer maintenance requirements, and better output quality can lead to cost savings over time. In high-volume printing businesses, the ability to produce top-tier prints without significant downtime or rework is a major advantage.

Output Quality: The Benefits of an 8-Color Printing Machine

When it comes to output quality, 8-color printing machines offer a range of advantages that help businesses produce prints that stand out. Here’s how the added colors improve the overall quality of printed materials.

1. Wider Color Gamut

The most noticeable benefit of 8-color printing is the expanded color gamut. By using additional colors like light cyan, light magenta, orange, and violet, the machine can produce a much wider range of hues than traditional CMYK printing. This allows for more accurate color reproduction, especially for complex images or designs with subtle gradients.

For businesses involved in packaging or marketing, where color consistency and vibrancy are critical to brand identity, this expanded color range ensures that the final product looks just as intended, with no loss of detail or vibrancy.

2. Smoother Gradients and Color Transitions

The light cyan and light magenta inks in an 8-color printing machine are particularly valuable for reproducing smooth gradients and subtle color transitions. These additional inks allow for more fine control over the color application, which is especially useful in printing images with soft transitions between colors, such as photographs or illustrations.

Without the extra inks, gradients can appear uneven or "banded" in 4-color printing, where distinct bands of color are visible rather than a smooth blend. In contrast, 8-color printing achieves seamless transitions and a more professional finish.

3. Enhanced Detail and Precision

The additional colors in an 8-color printer allow for higher precision when it comes to detailing in prints. Subtle tones, fine details, and intricate patterns are more accurately reproduced, making 8-color printing ideal for industries like fine art reproduction, high-end photography, and packaging design, where every detail matters.

The use of light cyan and light magenta inks helps produce finer tonal transitions, enhancing the overall resolution of the printed image. This is particularly important for applications requiring high levels of detail and clarity.

4. Vibrant and Realistic Colors

One of the most significant advantages of 8-color printing is the ability to produce vibrant, realistic, and true-to-life colors. The extra inks, particularly orange and violet, help enhance the depth and intensity of colors that can often appear flat or muted in 4-color printing. For businesses that rely on visually striking prints—such as those involved in creating product packaging, posters, or art prints—8-color printing ensures that the colors stand out and make an impact.

5. Better Reproduction of Pantone Colors

Pantone colors, which are standardized spot colors used in various industries, are often difficult to replicate with standard CMYK printing. However, the inclusion of additional colors such as orange and violet in an 8-color printing machine makes it easier to match these Pantone shades accurately. This is particularly valuable for businesses that need to maintain color consistency across different print materials, ensuring that their branding and designs are always on point.

Why Choose an 8-Color Printing Machine?

Choosing an 8-color printing machine ultimately comes down to the balance it offers between cost efficiency and output quality. Businesses that prioritize high-quality, vibrant prints with precise color accuracy can benefit immensely from the enhanced capabilities of an 8-color machine. The additional colors allow for more accurate color reproduction, better gradients, and sharper details, making it ideal for high-end printing applications such as packaging, fine art reproduction, and marketing materials.

Furthermore, the cost efficiency of an 8-color printing machine becomes apparent over time. Reduced ink waste, fewer reprints, and a decreased need for spot colors all contribute to the machine’s cost-effectiveness. While the initial investment may be higher, the long-term savings and improved print quality make it a smart choice for many businesses.

Conclusion

In today’s competitive printing industry, producing high-quality prints while managing costs is essential. An 8-color printing machine strikes the perfect balance between cost efficiency and output quality. With the ability to produce vibrant, accurate colors, smoother gradients, and intricate details, these machines are ideal for businesses that require premium prints.

By reducing the need for spot colors, minimizing waste, and producing high-quality results with greater consistency, an 8-color printing machine can be a valuable asset for any printing operation. Whether you are producing high-end packaging, fine art prints, or marketing materials, the investment in an 8-color printing machine is one that pays off in the long run.