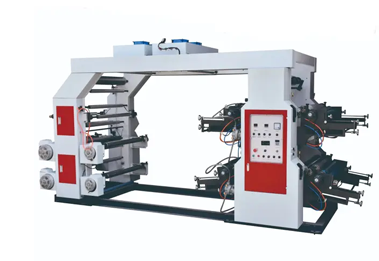

In today’s competitive business landscape, the ability to produce vibrant, accurate, and high-quality prints is essential across industries, from packaging and marketing to publishing and promotional design. The 4 Color Printing Machine, often referred to as CMYK printing, has become a cornerstone technology in achieving these standards. By combining four fundamental colors—Cyan (C), Magenta (M), Yellow (Y), and Key/Black (K)—this technology enables the production of a wide range of hues and shades, allowing businesses to create visually compelling and precise printed materials.

What is a 4 Color Printing Machine?

A 4 Color Printing Machine, utilizes the CMYK color model to reproduce full-color images. By combining cyan, magenta, yellow, and black in varying proportions, printers can generate an extensive color palette capable of producing detailed, realistic, and visually vibrant images. This is particularly important for designs that require high color accuracy, such as logos, photographs, marketing materials, and complex illustrations.

The CMYK model is widely used because it offers a balance between color fidelity and cost-effectiveness. Unlike spot color printing, which requires separate inks for each color, 4 color printing relies on just four basic inks, reducing material costs while maintaining quality. The ability to replicate consistent colors across multiple print runs makes it ideal for high-volume production in industries like packaging, publishing, and advertising.

The Printing Process Behind 4 Color Printing

The 4 color printing process involves several steps, each critical to achieving accurate, vibrant results:

Image Separation

The first step in 4 color printing is to separate the original image into four distinct layers—one for each color (cyan, magenta, yellow, and black). Specialized software analyzes the image and creates separate files for each color channel, ensuring that the final print will accurately reproduce all tones and details.

Printing in Layers

Once separated, each color is printed onto the substrate in successive passes. The printer applies each color in a specific order, carefully aligning them to ensure seamless blending. This layering technique is essential for achieving consistent color accuracy and sharp detail.

Overlapping and Color Mixing

As each layer is applied, the inks overlap to produce additional hues and shades. This additive process allows a 4 color printing machine to create a broad spectrum of colors from just four base inks. Proper alignment and ink density control are crucial to avoid color shifts and maintain the integrity of the final image.

Final Output

The result is a full-color print with accurate tones, smooth gradients, and intricate detail. High-quality 4 color printing ensures that printed materials reflect the intended design, whether for product packaging, advertising, or editorial content.

![4 Color Printing Machine 4 Color Printing Machine]()

Key Advantages of 4 Color Printing Machines

Using a 4 Color Printing Machine offers several significant benefits for businesses:

Superior Color Accuracy and Richness

The combination of CMYK inks enables printers to reproduce vibrant, detailed images with high fidelity. Photographs, intricate graphics, and complex designs retain their intended colors, providing professional-quality results that enhance brand perception.

Cost-Effectiveness for Large Volumes

For high-volume printing projects, 4 color printing is highly economical. Using only four base inks reduces material costs, making it ideal for bulk printing of packaging, brochures, banners, and promotional materials. This efficiency allows companies to achieve high-quality results without escalating production expenses.

Consistency Across Prints

Modern 4 color printing machines maintain color consistency across multiple print runs. Once the color profiles are calibrated, they can be replicated precisely, ensuring uniformity in product packaging, marketing collateral, and printed publications. Consistent color output reinforces brand recognition and maintains professional standards.

Versatility Across Materials

4 color printing is highly adaptable, suitable for a wide range of substrates including paper, cardboard, plastic, fabric, and even metal. Its versatility allows businesses in packaging, publishing, and advertising industries to leverage the same technology for diverse applications.

Key Components of 4 Color Printing Machines

High-quality 4 color printing machines incorporate advanced technologies to ensure precise and efficient printing:

Automatic Color Registration (ACR)

Automatic Color Registration is critical for aligning all four colors accurately. Machines equipped with ACR technology, such as those from Xingpai Machinery, minimize manual intervention, reduce errors, and ensure crisp, sharp edges in every print.

Advanced Ink Control Systems

Modern machines use precise ink control systems to regulate the flow and quantity of each color. This prevents issues like ink bleeding, oversaturation, and color inconsistencies. The result is vibrant, clear, and consistent prints, even for complex designs.

High-Speed Printing

Designed for efficiency, contemporary 4 color printing machines can handle large-scale print runs without compromising quality. High-speed operation is particularly beneficial in industries like packaging and advertising, where tight deadlines and bulk production are common.

Flexible Print Sizes

Depending on the model, these machines can accommodate various print sizes—from small business cards to large-format banners—providing versatility for different commercial needs.

Applications of 4 Color Printing Machines

The applications of 4 Color Printing Machine are extensive, spanning multiple industries:

Packaging Industry

In packaging, the ability to reproduce detailed graphics, logos, and full-color designs is crucial. 4 color printing machines allow businesses to create visually appealing packaging that enhances brand identity and product appeal.

Advertising and Promotional Materials

Posters, flyers, brochures, and banners benefit from vibrant, high-quality printing. 4 color printing ensures marketing materials are eye-catching and accurately reflect the brand’s visual identity.

Publishing Industry

From glossy magazine covers to detailed book illustrations, 4 color printing delivers professional-quality results with consistent color reproduction, essential for editorial credibility and reader engagement.

Label and Tag Printing

High-quality labels and tags require precise color reproduction to convey product information and branding effectively. 4 color printing machines meet these requirements, ensuring both functionality and visual appeal.

Security Printing

Industries that require security features, such as currency, certificates, or tickets, leverage 4 color printing to produce intricate multicolored designs that are difficult to replicate, ensuring authenticity and security.

Challenges and Solutions in 4 Color Printing

While 4 color printing is highly versatile, it presents some challenges:

Color Matching and Consistency

Achieving accurate color reproduction across different substrates and printers can be difficult. Advanced color management systems, including calibrated color profiles and software adjustments, help maintain consistency.

Ink Drying Time

Ink drying can be a concern, especially on non-porous materials. Modern machines, including those from Xingpai, incorporate faster drying systems to reduce production delays.

Material Limitations

Certain textures or substrates may not absorb CMYK inks effectively. Proper material selection and machine adjustments ensure optimal results across diverse surfaces.

Conclusion

The 4 Color Printing Machine remains one of the most versatile and widely used printing technologies. It combines high color fidelity, cost efficiency, consistency, and adaptability, making it an essential tool for packaging, marketing, publishing, and more.

With features like automatic color registration, advanced ink control, high-speed operation, and print size flexibility, companies like Xingpai Machinery continue to set benchmarks in printing quality and reliability. Whether producing bulk packaging, promotional materials, or high-end publications, 4 color printing technology ensures precision, efficiency, and professional results.

To explore how Xingpai’s 4 color printing machines can elevate your printing operations and enhance brand quality, visit Xingpai Machinery.