Print durability and wear resistance are key in the printing industry, especially for packaging, textiles, and labels. Durable prints maintain their quality over time, withstanding environmental factors like UV rays, moisture, and physical wear. In packaging and labels, prints need to stay intact despite exposure to light or rough handling. In textiles, durable prints ensure designs don’t fade after washing.

Achieving durability involves using high-quality inks, selecting the right substrates, and managing environmental factors. Inks must resist fading and abrasion, while the printing process must ensure consistent application and proper drying.

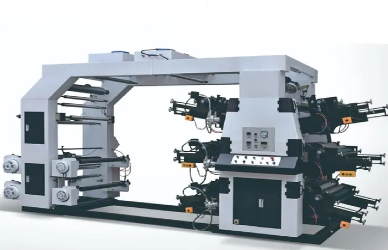

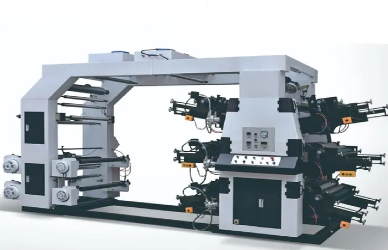

6 Color Printing Machines enhance durability by using six colors—CMYK plus two additional shades. This expanded color range improves print vibrancy, accuracy, and longevity, making them ideal for high-quality, precise prints in industries requiring durability and color consistency.

The Role of Ink Systems in Durability

1.Advanced Ink Formulations

Ink formulations in 6 Color Printing Machines are designed to improve both color accuracy and durability. Advanced inks, made with a mix of organic and synthetic components, resist fading, abrasion, and environmental damage, ensuring long-lasting prints.

2.High-Quality Inks for Longevity

Premium inks are essential for durable prints. High-pigment inks provide better color retention and resistance to environmental factors like UV rays, moisture, and abrasion, making them ideal for packaging, labels, and other high-exposure applications.

3.UV and Water-Based Inks

UV Inks: These inks cure under ultraviolet light, creating a strong bond to the substrate. They resist UV degradation, making them suitable for outdoor and high-exposure uses.

Water-Based Inks: These eco-friendly inks offer excellent adhesion and resistance to wear. They are ideal for packaging and applications where environmental impact is a concern.

4.Ink Adhesion and Bonding

For durability, ink must adhere well to various substrates like paper, plastics, and films. Strong ink bonding prevents peeling and fading, even under harsh conditions. Specialized formulations ensure that inks bond effectively with flexible or rigid materials.

5.Coatings and Additives for Improved Durability

To enhance longevity, coatings and additives such as UV coatings, anti-scratch layers, and waterproof treatments are used. These provide extra protection, preserving print quality and resistance to fading, moisture, and physical damage.

The Impact of Printing Process on Durability

1.Precision and Consistency in Ink Distribution

Uniform ink distribution is essential for durable prints. In 6 Color Printing Machines, precise ink application ensures strong, long-lasting prints.

Achieving Uniform Ink Application: Advanced rollers and plates in 6 Color Printing Machines control ink flow, applying it evenly across the substrate. This consistent ink layer enhances print strength and resistance to fading, abrasion, and wear.

Minimizing Ink Inconsistencies: By calibrating the printing process, these machines reduce issues like over-inking or under-inking, ensuring consistent color and improved durability.

2.Advanced Drying Technology

Efficient drying is crucial for preserving print quality and durability. 6 Color Printing Machines use UV curing or air drying systems to ensure proper ink adhesion and resistance to damage.

Importance of Efficient Drying (UV or Air Drying): UV curing instantly hardens the ink, creating a strong bond to the substrate, while air drying works for water-based inks, ensuring efficient drying without compromising print quality.

How Drying Technology Prevents Smudging and Fading: Advanced drying technology prevents smudging during production and helps maintain color integrity, reducing fading and degradation over time.

Substrate Compatibility and Durability

1.Ability to Print on Diverse Materials

6 Color Printing Machines are designed to print on a wide range of substrates, including plastics, films, foils, and paper. This versatility allows for high-quality prints across various applications, such as packaging, labels, and textiles.

Impact on Print Resistance: The substrate directly affects durability. For example, plastics and foils are more resistant to moisture and abrasion, while paper may need additional coatings for improved longevity.

2.Impact of Substrate Choice on Wear and Environmental Resistance

Different substrates influence how well prints withstand environmental factors and physical wear.

Resistance to Wear: Films and foils are more durable and can handle rough conditions better than paper, making them ideal for packaging and products that experience frequent handling.

Environmental Resistance: Materials like plastic or foil offer better protection against UV light and moisture, while textiles or paper might need specialized inks or coatings to resist fading and wear.

3.Flexible Printing Capabilities

6 Color Printing Machines offer flexibility, printing effectively on both rigid and flexible materials, which enhances durability in various applications.

Flexible Materials: For materials like films and fabrics, the machine ensures prints remain intact despite bending or folding.

Rigid Materials: On materials like cardboard, the machine delivers durable prints for packaging, which need to withstand handling during transport and storage.

Resistance to Environmental Factors

1.Weather and UV Resistance

6 Color Printing Machines offer prints that are highly resistant to sunlight and harsh weather, making them ideal for outdoor use.

UV Resistance: UV-protected inks and coatings help prints maintain their vibrancy even when exposed to sunlight for long periods. These inks cure under UV light, offering excellent protection against fading and degradation in outdoor applications like signage, labels, and packaging.

Role of UV-Protected Inks and Coatings: Special coatings with UV-blocking agents ensure that prints remain intact and durable, especially for products exposed to the elements, such as automotive decals or outdoor advertisements.

2.Chemical and Abrasion Resistance

6 Color Printing Machines also provide prints that are resistant to chemicals, water, and abrasion, making them suitable for challenging environments.

Chemical and Water Resistance: Solvent-based and UV inks are designed to resist moisture, oils, and chemicals, ensuring the print lasts in demanding conditions like food packaging or chemical labeling.

Abrasion Resistance: The precision of ink application and curing helps prints resist wear and tear. This is particularly useful for industries like automotive and industrial printing, where products are exposed to frequent handling.

3.Common Industries That Benefit

Several industries benefit from these durable prints:

Automotive: Durable prints on labels, decals, and trim resist weathering and wear.

Food Packaging: Chemical and moisture resistance keeps prints intact for food products.

Outdoor Advertising: UV and weather-resistant prints are ideal for billboards and signage.

![6 Color Printing Machine 6 Color Printing Machine]()

Long-Term Cost Efficiency of Durable Prints

1.Reduced Need for Reprints and Replacements

6 Color Printing Machines produce durable prints that resist fading and wear, cutting the need for frequent reprints. This lowers costs for ink, materials, and labor, especially in high-volume industries like packaging and labeling. Fewer replacements mean smoother operations and less waste.

2.Maintaining Brand Integrity

Durable prints also protect brand image. Packaging and labels that stay vibrant and intact enhance product appeal and customer trust. In competitive markets such as food, cosmetics, and retail, consistent high-quality prints help brands stand out and maintain recognition.

Conclusion

Durability and wear resistance are vital in modern printing, and a 6 Color Printing Machine is built to meet these needs with advanced ink systems, efficient drying, and compatibility with diverse substrates like plastics, foils, and textiles. These features ensure prints resist fading, abrasion, and environmental stress, maintaining quality from production to end use.

For businesses, the right 6 Color Printing Machine offers more than vibrant color—it reduces reprints, lowers costs, and protects brand integrity. In competitive sectors such as food packaging, automotive, and consumer goods, durable prints strengthen market presence and customer trust.

As packaging and printing industries evolve toward greater sustainability and higher standards, durable printing will become even more important. By investing in 6 Color Printing Machines, businesses can achieve reliable, long-lasting results while staying competitive in a demanding market.